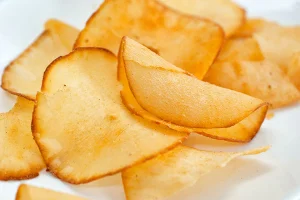

Potato-based snacks like potato chips and french fries are among the most popular and profitable products in the global food market. For manufacturers and food processing businesses, understanding the potato processing line and selecting the right potato processing machinery is essential to ensure high efficiency, consistent quality, and food safety.

In this guide, we’ll walk through:

The full potato chips and french fries processing workflow

What potato processing equipment is required at each stage

How to choose the right potato chips processing machine or french fries processing equipment

Key considerations for international buyers

Step-by-Step: Potato Processing Line Workflow

Whether producing crispy potato chips or frozen french fries, the core processing steps are quite similar at the early stages, with variations in slicing, frying, and freezing. Below is a breakdown of the standard potato chips processing line and french fries processing line:

1. Potato Cleaning and Washing

Purpose: Remove dirt, soil, and surface impurities.

Machines Used:

Potato washing machine

Seifenblasen-Reinigungsmaschine

Brush roller cleaning machine (for tough skin)

2. Peeling

Purpose: Remove potato skin while minimizing flesh loss.

Machines Used:

Potato peeling machine (abrasive or knife-type)

Often integrated with washing units for continuous flow

3. Slicing or Cutting

Purpose: Shape the potatoes according to the end product—chips or fries.

Machines Used:

Potato chips slicer – for thin, uniform chip cuts

French fries cutting machine – for matchstick or crinkle-cut fries

4. Rinsing and De-starching

Purpose: Remove excess starch to prevent sticking and browning during frying.

Machines Used:

Rinsing tanks

Starch removal system

5. Blanching

Purpose: Pre-cook the potatoes to maintain color, texture, and shelf life.

Machines Used:

Blanching machine (hot water or steam type)

6. Dewatering (for chips) / Drying (for fries)

Purpose: Remove surface moisture before frying.

Machines Used:

Centrifugal dewatering machine

Air drying machine

7. Frying

Purpose: Cook the potatoes and develop flavor and texture.

Machines Used:

Continuous fryer

Oil filter system

8. Oil Removal / Cooling

Purpose: Remove excess oil and bring product to ambient temperature.

Machines Used:

Oil removing machine

Cooling conveyor

9. Seasoning (Optional)

Purpose: Add flavoring to chips or fries.

Machines Used:

Seasoning drum

Spray system for powder or liquid flavor

10. Freezing (for french fries only)

Purpose: Extend shelf life of frozen fries.

Machines Used:

Quick freezer (IQF freezer)

11. Packaging

Purpose: Final packing for retail or wholesale distribution.

Machines Used:

Automatic packaging machine

Weighing and labeling systems

Why Choose Wanlong Potato Processing Solutions?

With over 17 years of manufacturing expertise, Wanlong Food Processing Machinery provides one-stop solutions for:

Potato chips processing lines

French fries processing lines

Custom potato processing equipment

As a direct factory manufacturer, we offer:

Customizable solutions for small to industrial-scale production

Factory-direct pricing

CE-certified machines for global export

Full technical support and layout design services

Final Thoughts

Investing in the right potato chips processing machine or french fries processing equipment is key to running a successful food processing business. Whether you need a full potato processing line or a specific machine like a french fries cutting machine, working with a reliable manufacturer ensures product quality, efficiency, and scalability.