Fish Processing Machinery

1. Fish Killing Machines: These ensure a quick and humane killing process, reducing stress and preserving meat quality.

2. Fish Skinning Machines: Used to remove fish skin efficiently, leaving behind clean, high-quality fillets.

3. Fish Filleting Machines: These machines fillet fish into uniform portions, increasing yield and reducing manual labor.

These machines are commonly used in seafood processing plants, supermarkets, and fish markets, where efficiency, hygiene, and quality are essential. They are characterized by their high processing speed, precise operations, and ease of use, making them ideal for large-scale fish processing operations. Additionally, many machines are designed for easy cleaning and maintenance, ensuring long-term durability in a demanding environment.

Types of Fish Processing Machinery

Vertical fish skinning machine

Model: SC-400

Power: 750W

Voltage: 220V/380V, 60Hz, three-phase

Dimensions: 620*570*900mm

Output: 30-60 pieces/minute

Feed port size: 400mm

Weight: 98kg

Desktop fish skiner machine

Model: SC-1500

Power: 200W

Voltage: 220V

Weight: 48kg

Dimensions: 540*420*410mm

Processing speed: 20-30 pieces/minute

Fish Cutting Machine

Voltage: 220V/ 380V

Dimensions: 830*870*820mm

Efficiency: 500 slices/minute

Application: Suitable for beveling salmon, squid, pork, beef, tripe, liver and other meats.

Solicite un presupuesto gratuito

Fish Filleting Machine

Model: YQ-430

Power: 1.5KW

Voltage: 380V

Size: 1000*700*1060mm

Output: 500kg/h

Feeding port width: 430mm

Cutting size: Customized on demand

Aplicación

Fish processing machines are used in seafood processing plants to efficiently clean, fillet, skin, and package fish, ensuring high-quality products for commercial and industrial use.

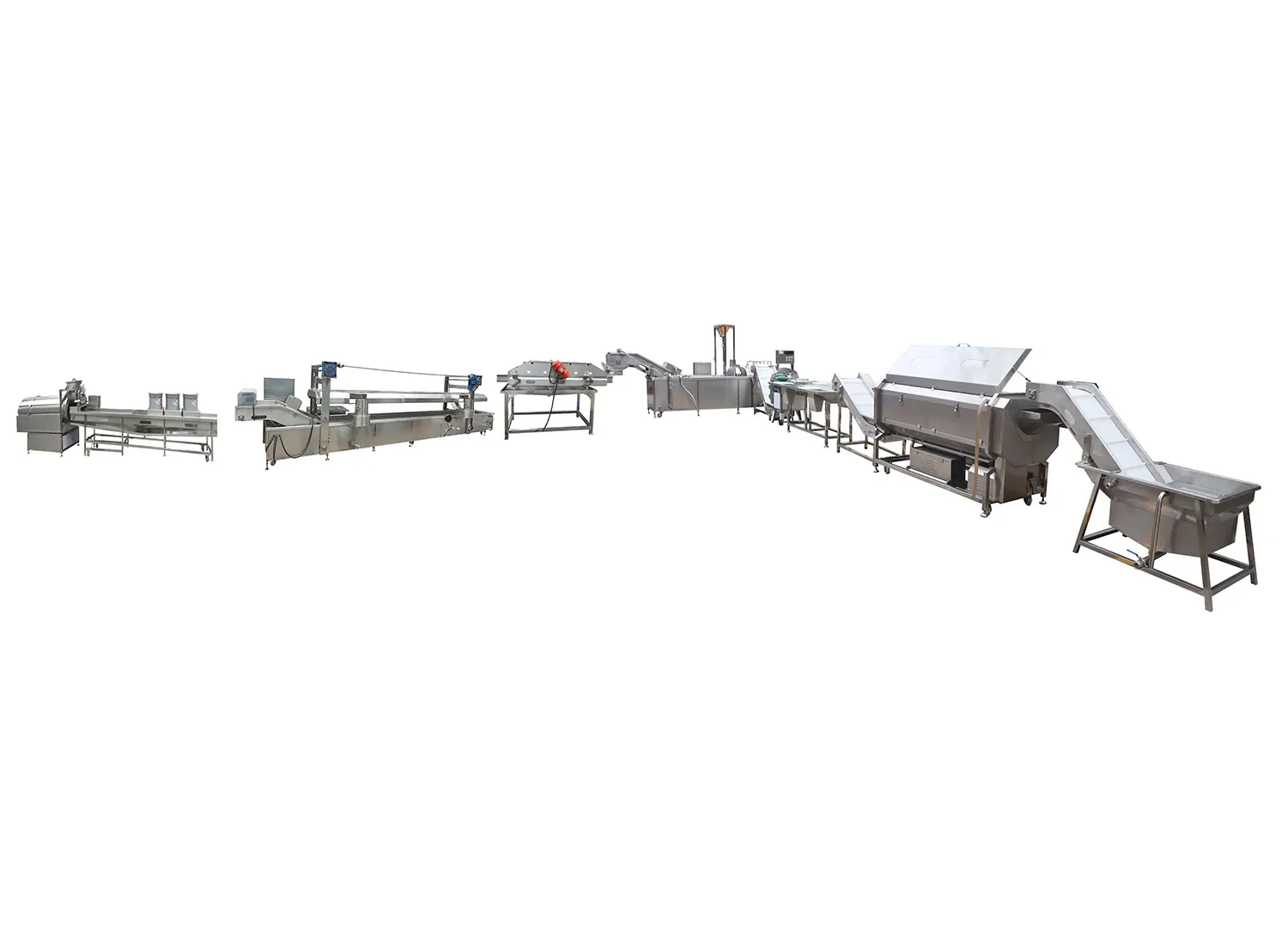

Línea de producción de procesamiento personalizado OEM

Línea de producción de patatas fritas

Remojo del pienso → limpieza y pelado → elevador → línea de picking → elevación del pienso → cortadora → enjuague del almidón → escurrido por vibración → línea de fritura → desengrasado por viento → sazonado.

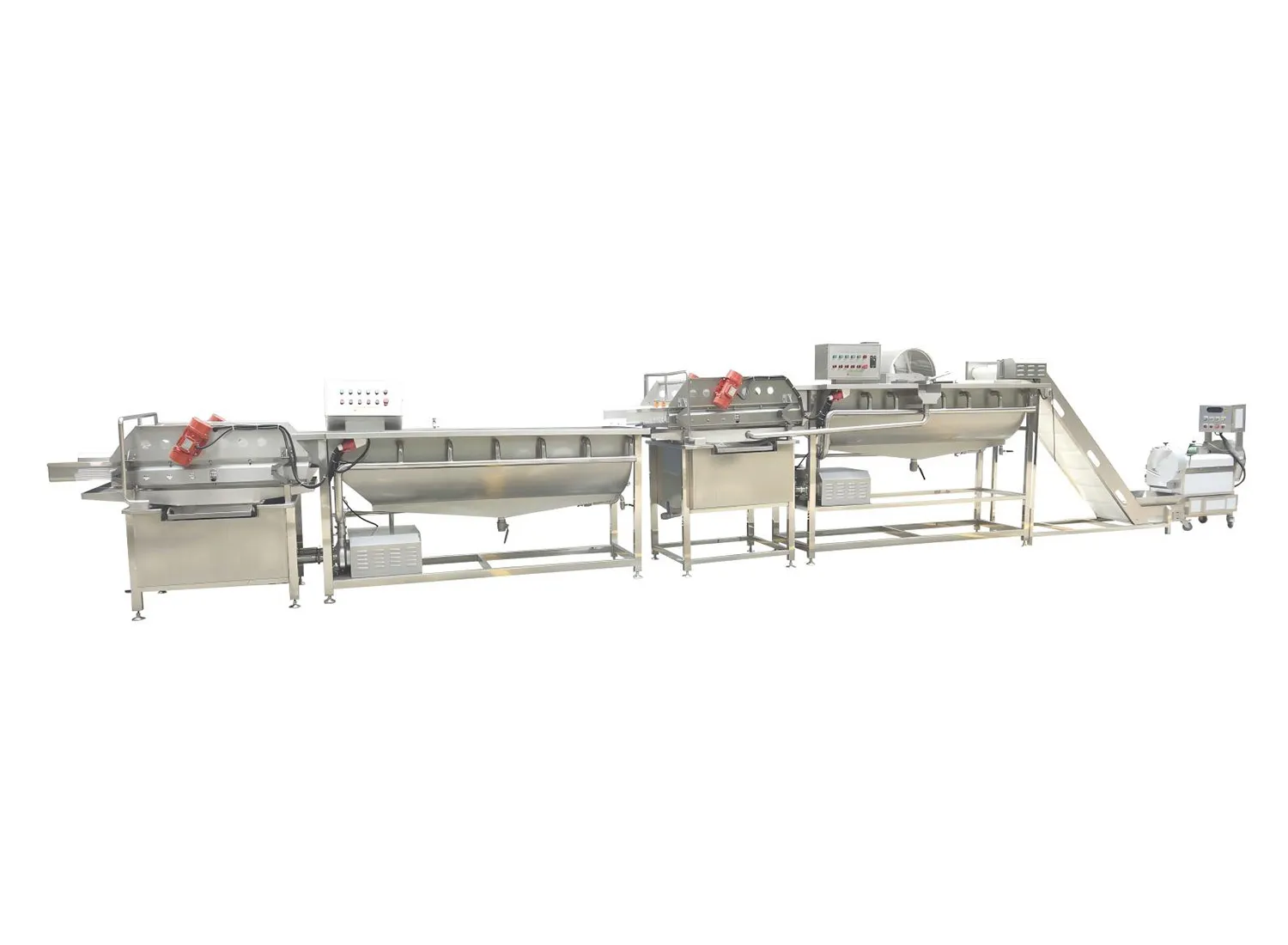

Limpieza y secado al aire de la línea de fritura

Alimentación por elevación → limpieza y pelado → línea de recogida → alimentación por elevación → cortadora → enjuague de almidón → escurrido por vibración → escurrido por soplado de viento → alimentación por elevación → línea de fritura.

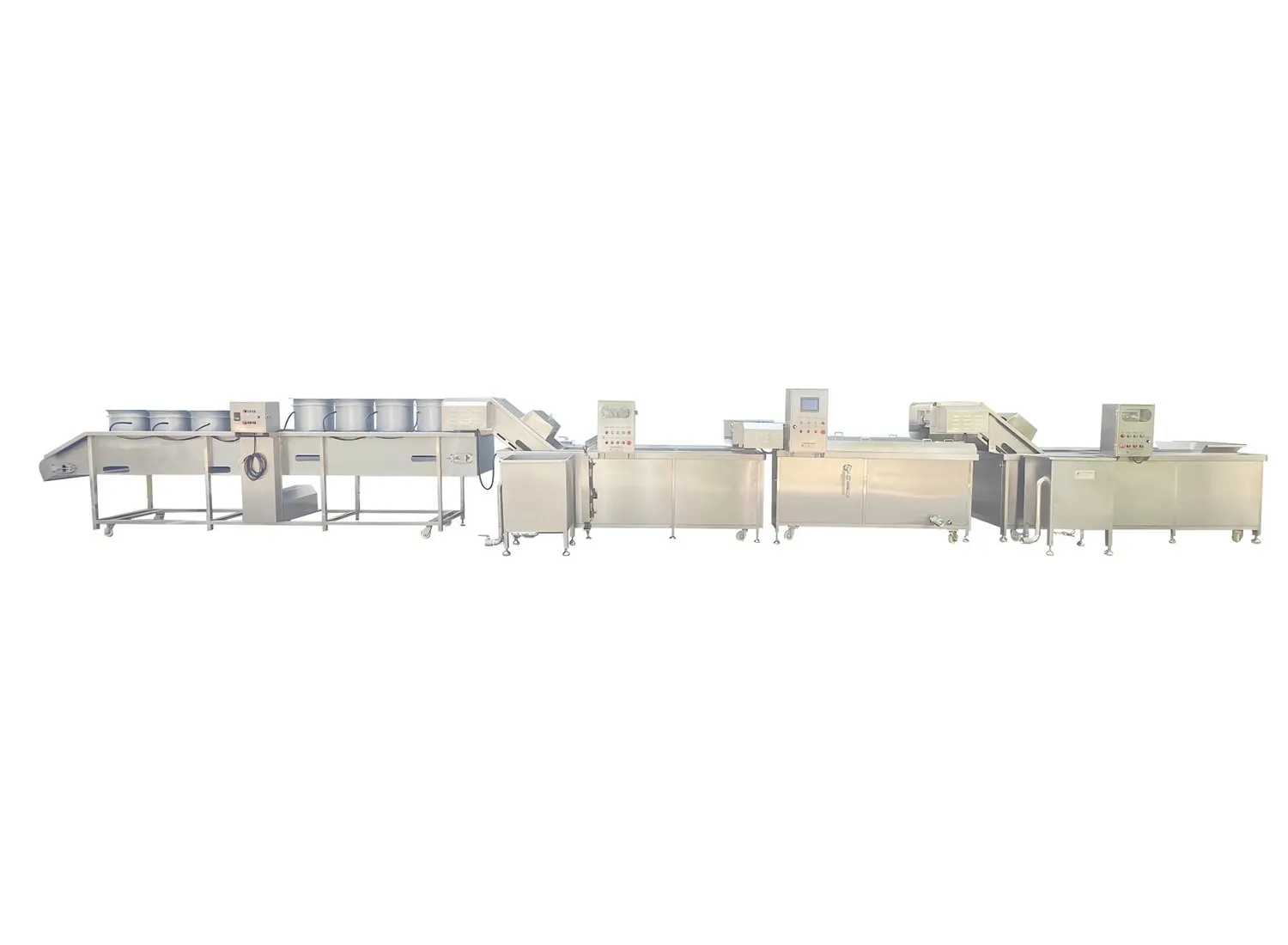

Línea de producción de ensaladas

Corte de alimentación → elevación y transporte → línea de limpieza → limpieza secundaria → drenaje por vibración → eliminación de agua y secado al aire → envasado.

Línea de lavado y escaldado de carne

Alimentación por elevación → limpieza → línea de escaldado → máquina de limpieza → línea de secado por aire.

Processing Effect

1. Improved Efficiency: These machines significantly speed up processing times, allowing for high-volume production.

2. High-Quality Output: Ensures precise and clean results, with uniform fillets, slices, and skin removal.

3. Consistent Performance: Delivers consistent processing results, reducing variability and ensuring high standards.

4. Labor Reduction: Minimizes the need for manual labor, increasing productivity and reducing human error.

5. Hygiene and Safety: Designed to meet food safety standards, ensuring clean, hygienic processing with minimal contamination risk.

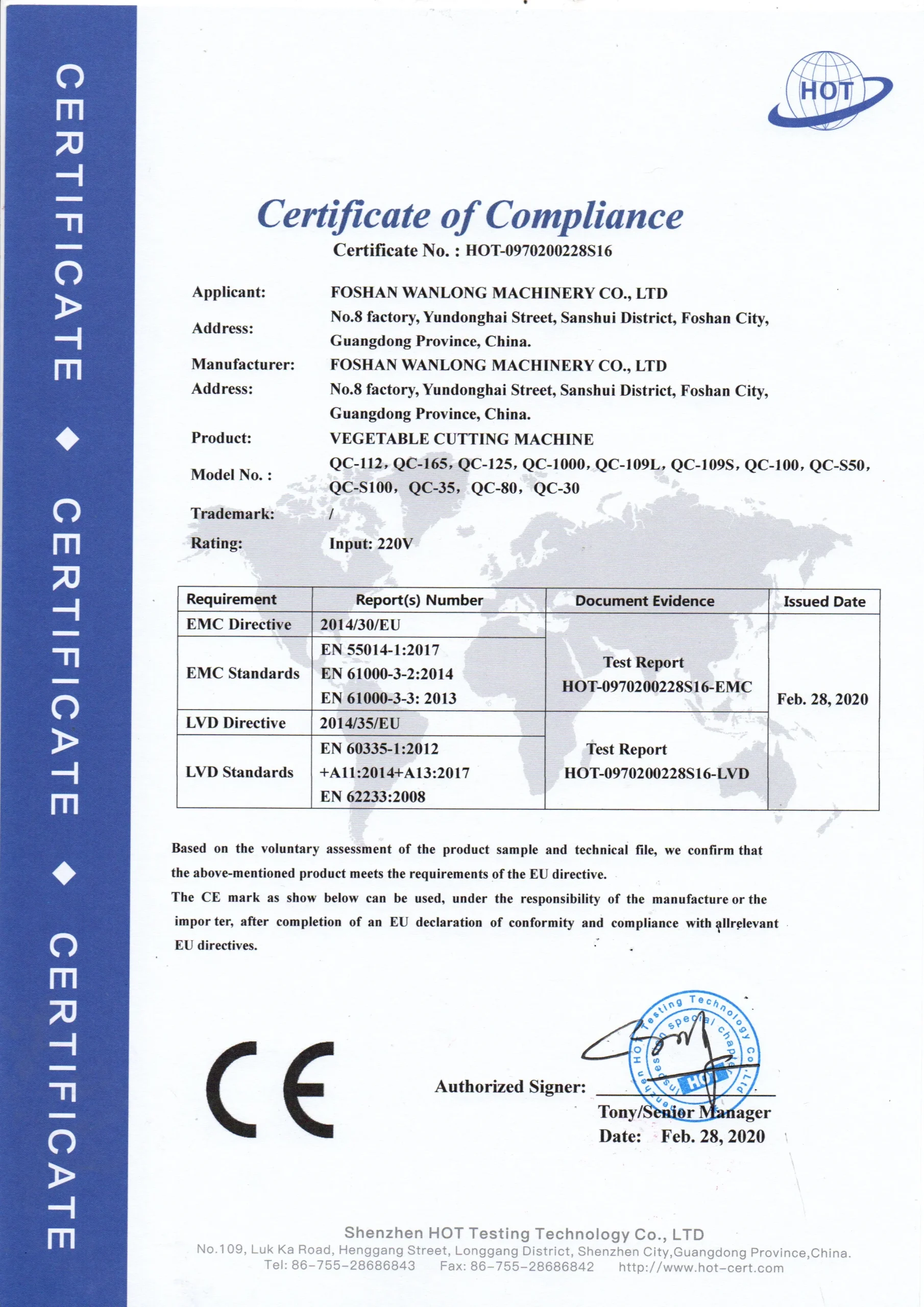

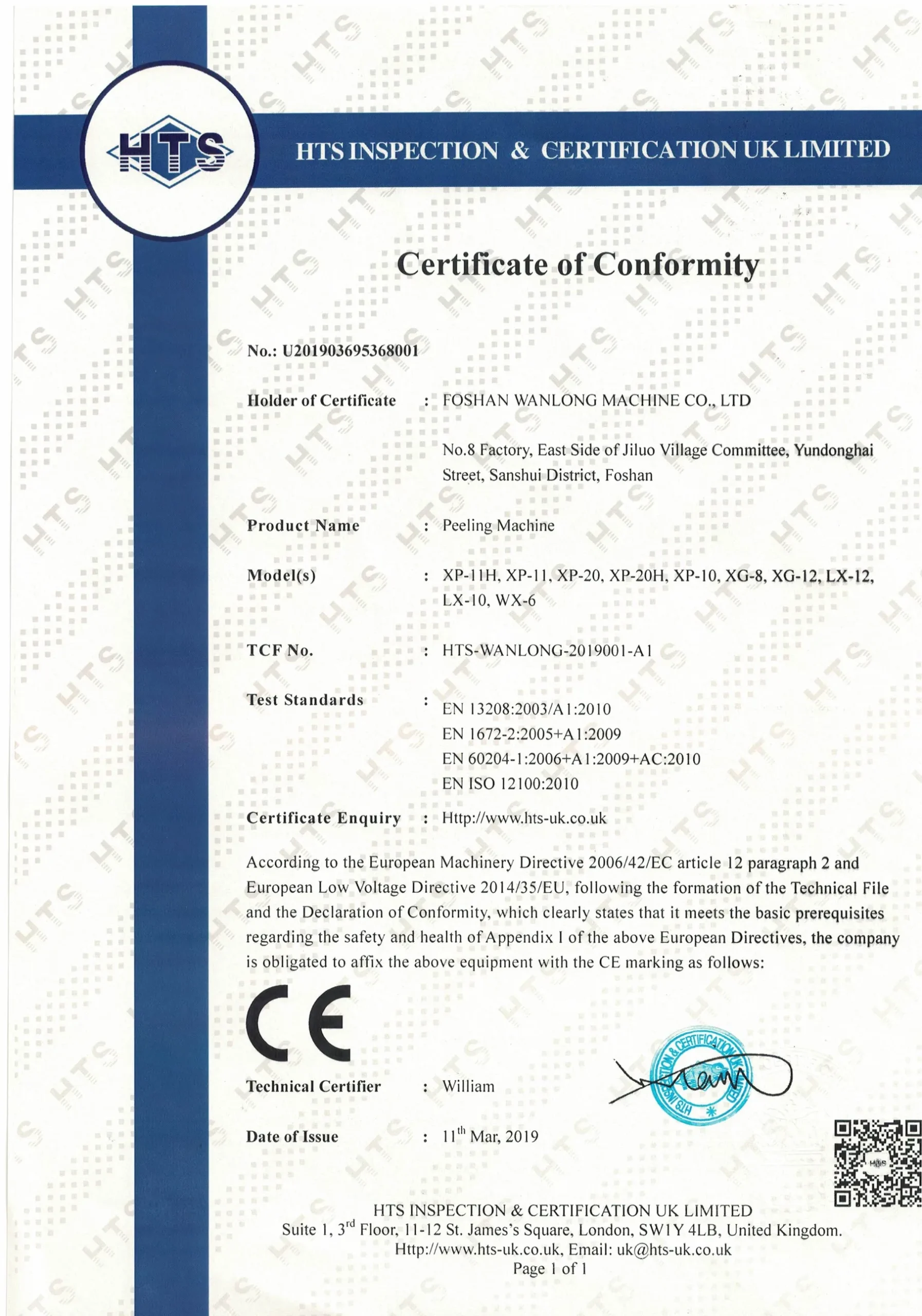

Nuestros certificados

¿Listo para obtener la máquina de limpieza para alimentos?

Póngase en contacto con nosotros para obtener una consulta gratuita

Preguntas frecuentes

We offer fish killing machines, skinning machines, filleting machines, slicing machines, and skin shredding machines for efficient fish processing.

Our fish killing machines humanely and quickly kill fish, ensuring high-quality meat and improving processing speed.

Fish skinning machines remove skin efficiently with minimal meat loss, speeding up processing and reducing labor.

Yes, our fish slicing machines can process various fish like salmon, tuna, and tilapia, providing precise, uniform slices.

The fish skin shredding machine efficiently shreds fish skin into uniform pieces, ideal for pet food or other applications.

Automated machines reduce labor, ensure consistent quality, and improve processing speed while enhancing hygiene.