Fruit cleaning and peeling machine

The roller peeling cleaning machine can be customized according to customer needs, and the hardness of the brush can achieve the cleaning or peeling function.

The equipment is equipped with a waste collection tray at the bottom, which is easy to disassemble and prevents sewage and dandruff from polluting the ground and clogging the sewage outlet. When the material to be cleaned or peeled enters the horizontal rotating brush, the brush repeatedly rubs against each other in the same rotating direction (from high to low) of the brush cleaning (peeling) machine to achieve the purpose of cleaning (peeling).

The cleaning roller brush is made of nylon rope rolled material treated with special technology and is durable.

Types of Cleaning and Peeling Machine

Brush cleaning and peeling machine

Product model: QX-08

Product material: All stainless steel

Specifications: 900*1060*1220mm

Wool roller length: 800mm

Wool stick quantity: 6

Power: 1.5KW

Voltage: 220V/380V

Output: 600kg/hour

Weight: 187kg

Hair roller cleaning and peeling machine

Model: QX-12

Material: All stainless steel

Specifications: 1500X900X1220mm

Length of brush roller: 800mm

Number of brushes: 6

Power: 1.5KW

Voltage: 380V

Output: 1.8~2 tons/hour

Weight: 160kg

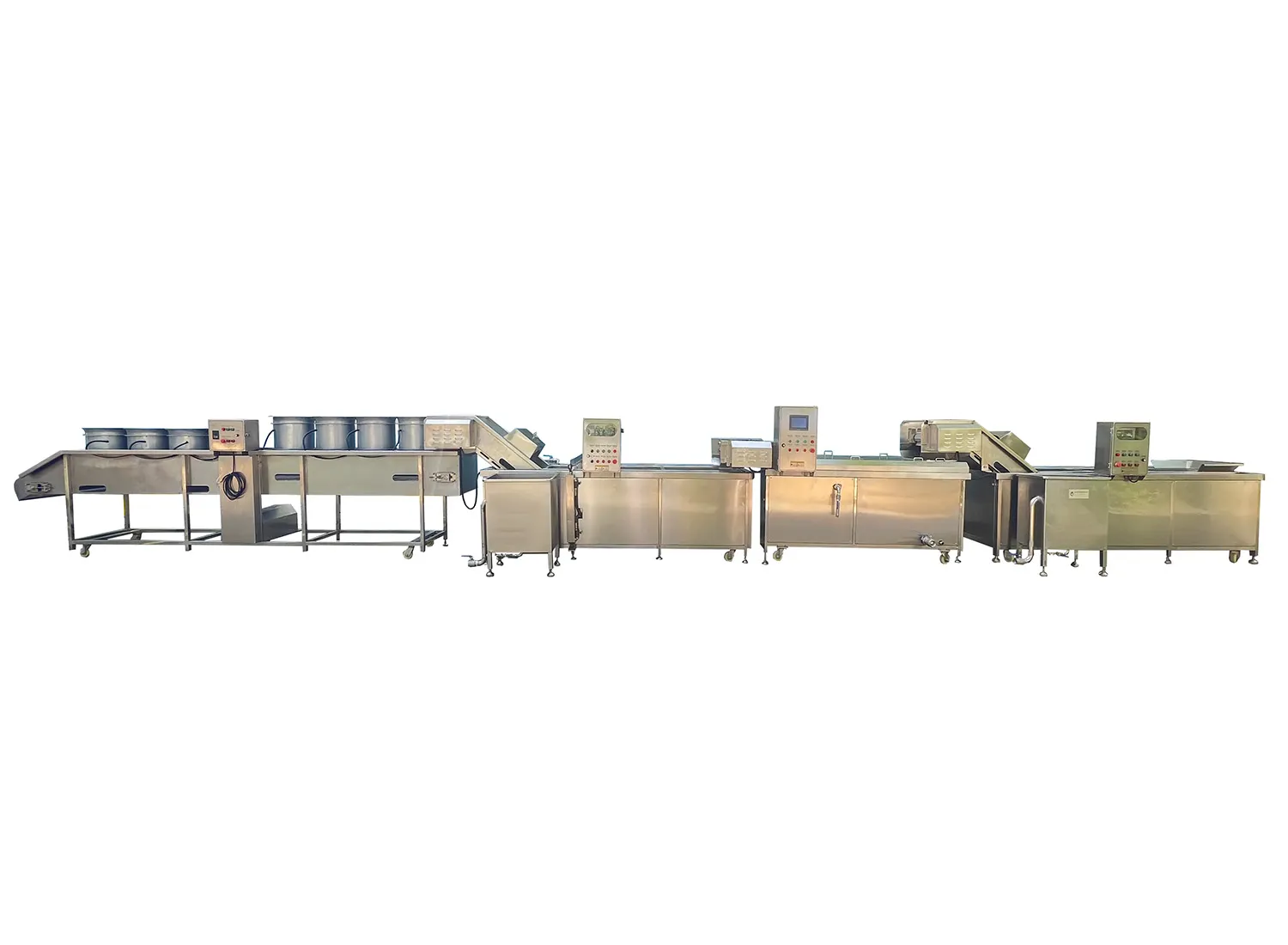

Fruit cleaning and peeling machine

Product model: QX-18

Product material: All stainless steel

Specifications: 2350X850X800mm

Wool roller length: 1800mm

Wool roller quantity: 8

Power: 2.2KW

Voltage: 380V

Output: 3 tons/hour

Weight: 250kg

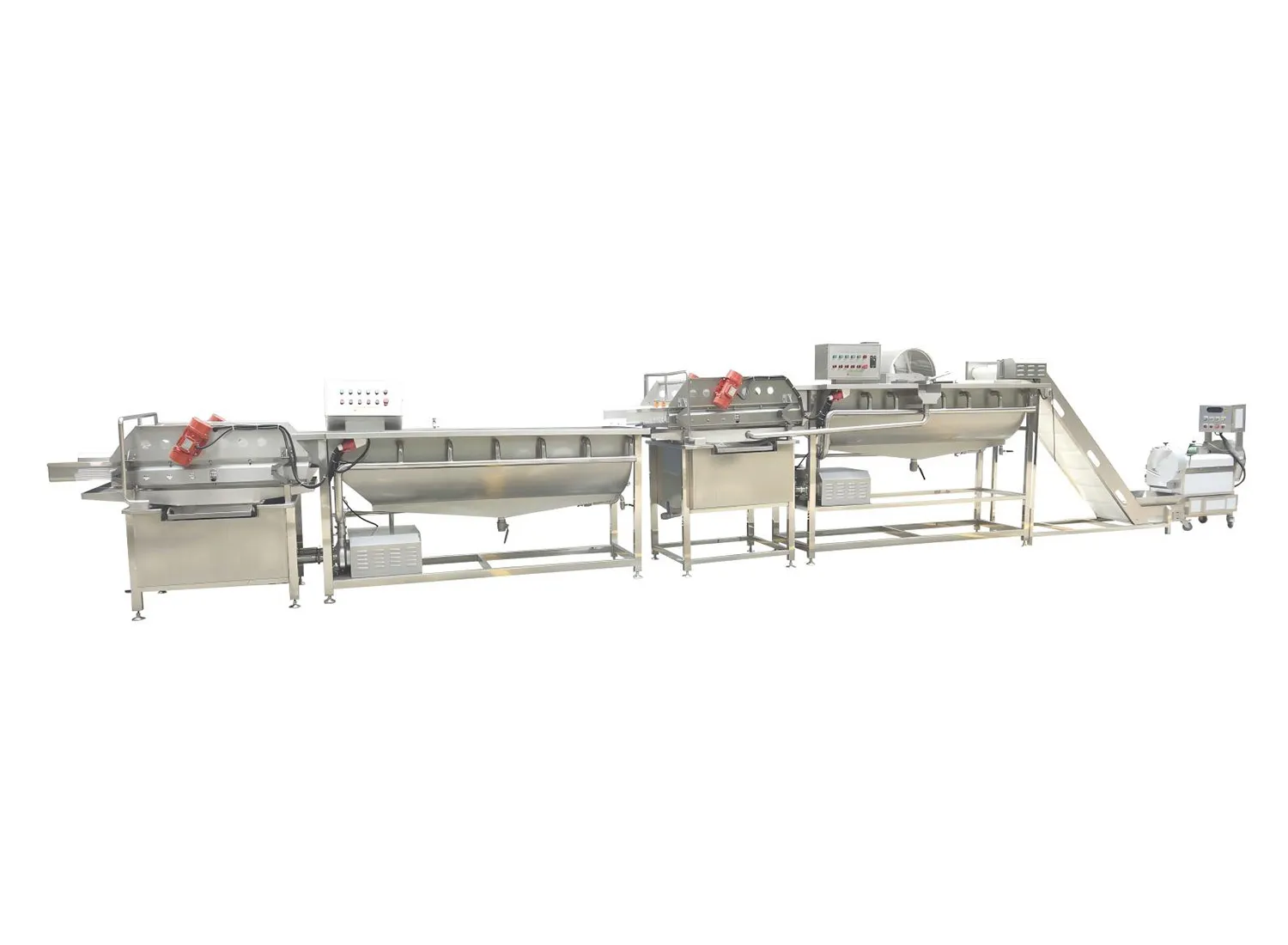

Spiral cleaning and peeling machine

Model: LX-23

Product material: All stainless steel

Dimensions: 3000*880*1550mm

Capacity: 2000-3000 kg/hour

Voltage: 380V/3 phase (customized)

Horsepower: 3 kW

Drum length: 2.3m (8 pieces)

Get a free quote

Application

This cleaning and peeling machine is widely used for cleaning and peeling round and oval fruits and vegetables such as ginger, white radish, carrot, taro, peanut, potato, sweet potato and other root vegetables.

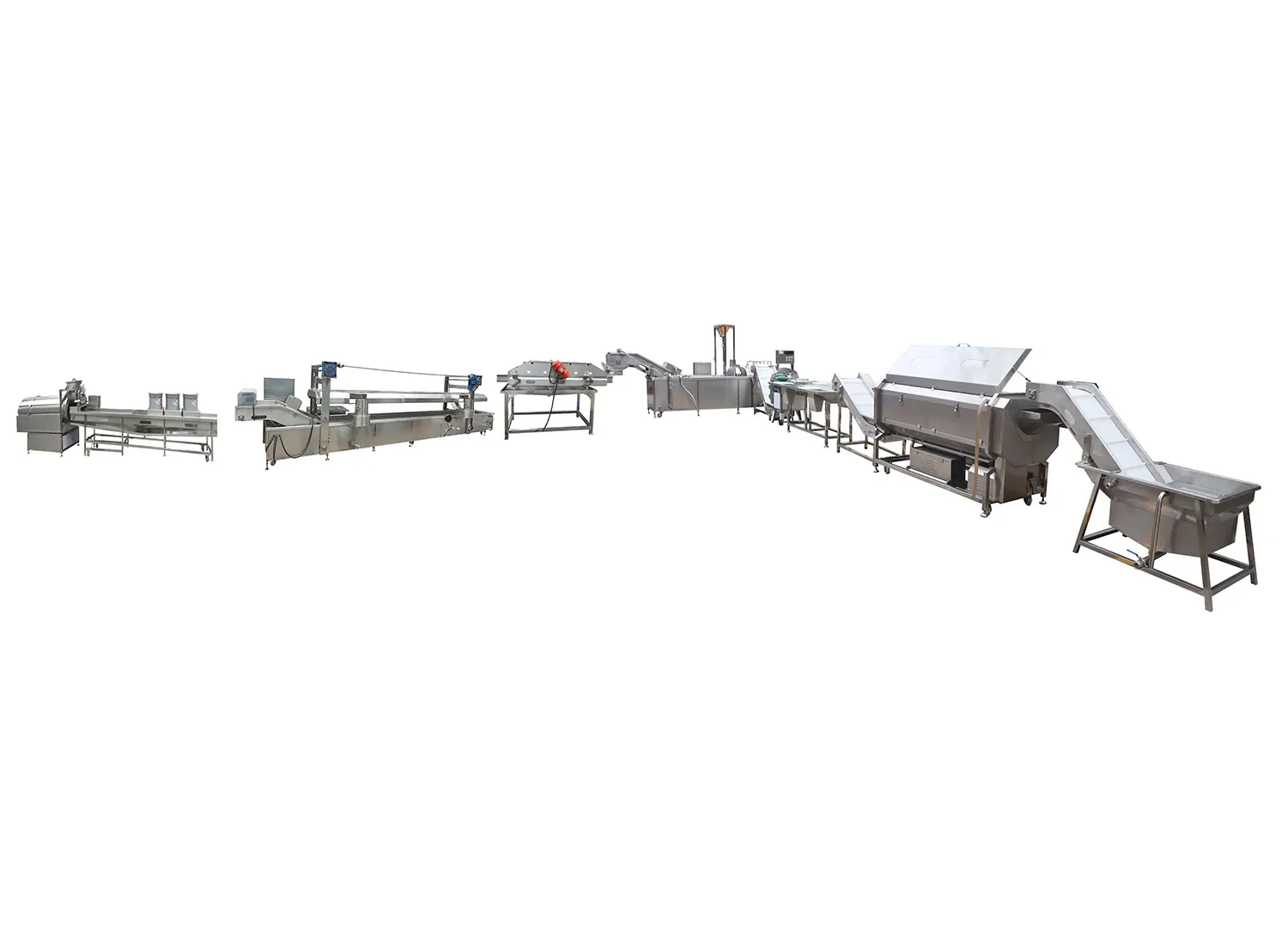

OEM Customized Processing Production Line

Potato Chips Production Line

Feed soaking → cleaning and peeling → elevator → picking line → lifting feed → slicer → rinsing starch → vibration draining → frying line → wind degreasing → seasoning

Cleaning and Air Drying Frying Line

Lifting feed → cleaning and peeling → picking line → lifting feed → slicer → rinsing starch → vibration draining → wind blowing draining → lifting feed → frying line

Salad Vegetable Production Line

Feed cutting → lifting and conveying → cleaning line → secondary cleaning → vibration drainage → water removal and air drying → packaging

Meat Washing and Blanching Line

Lifting feed → cleaning → blanching line → cleaning machine → air drying line

Cleaning and Peeling Machine Effect

1. Removable grinding rod structure

The grinding rod is equipped with nylon brush/corundum rod, which can effectively and quickly handle material cleaning and peeling

2. Working condition perspective panel

The machine operation status is clear at a glance

3. Control switch

Variable frequency control can be performed according to material size and output speed

4. Water supply spray device

Single-row independent water supply spray device, water-saving and environmental protection

5. Adjustable fixed base

The adjustable height fixed base is suitable for production lines with different requirements.

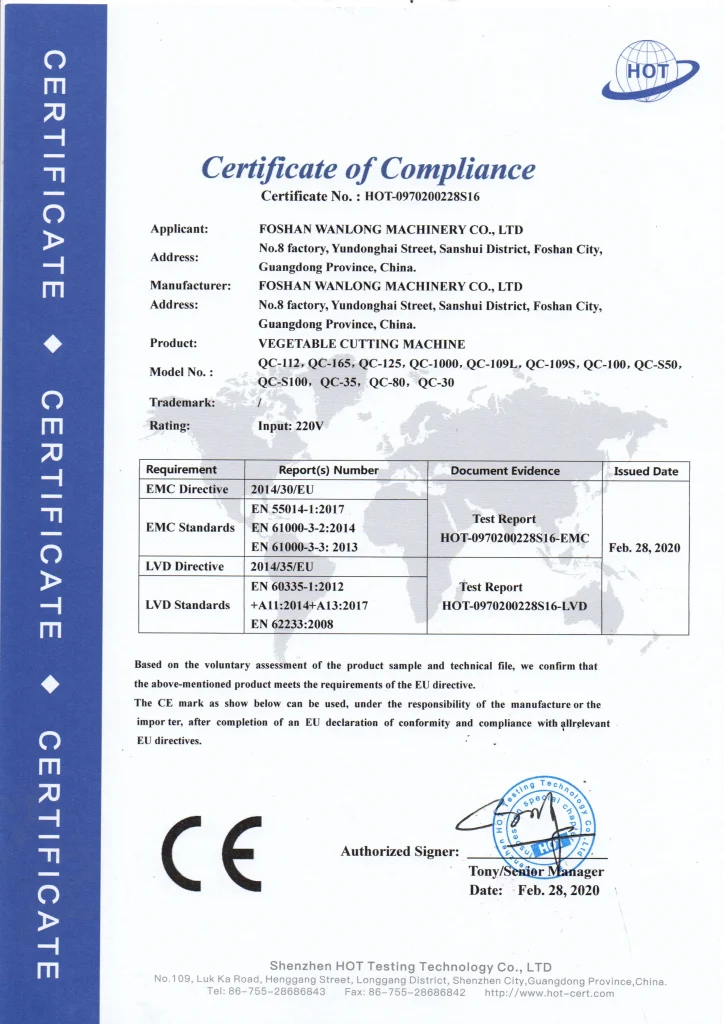

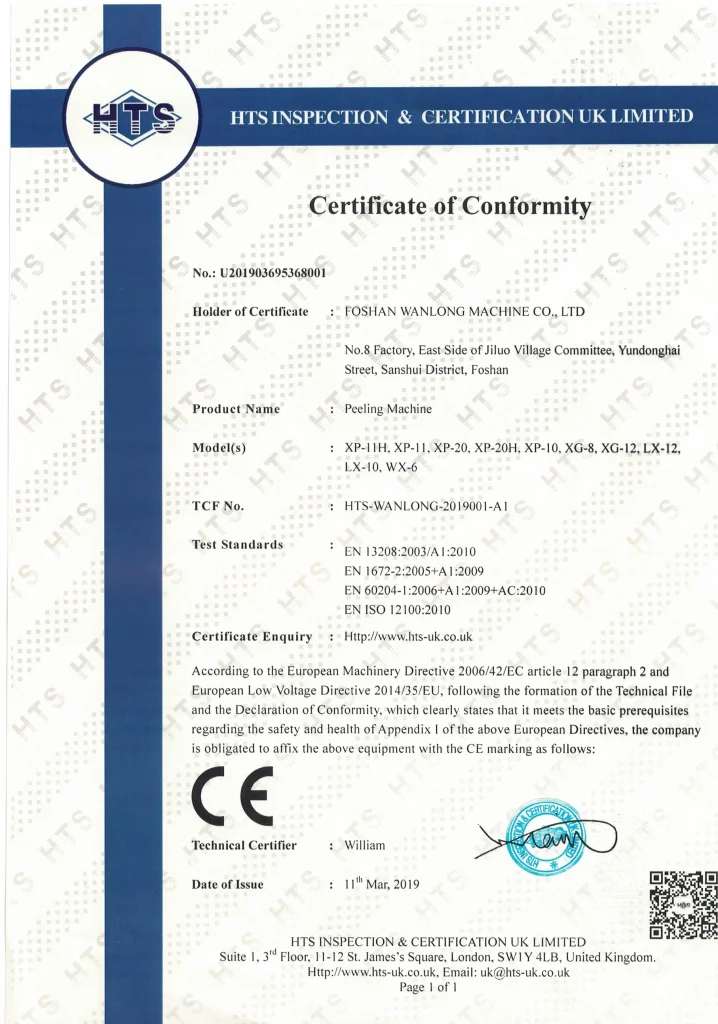

Our Certificates

FAQs

Our washing and peeling machines are designed to handle a wide range of fruits and vegetables, including ginger, white radish, carrot, taro, and more. The machines are customizable to suit different produce based on size, texture, and peeling requirements.

Our machines are highly efficient, designed to wash and peel large volumes of fruits and vegetables in a short period. With automated washing, peeling, and sorting processes, we help reduce labor costs while improving processing speed and product quality.

Yes, our fruit and vegetable washing and peeling machines are designed with ease of cleaning in mind. The components are made from stainless steel, making them resistant to corrosion and easy to maintain. We also provide detailed maintenance instructions to ensure long-term, reliable performance.

Yes, we offer tailored solutions to meet your specific needs. Whether it’s adjusting the size of the peeling blades or integrating a special washing process, we can customize our machines to align with your production demands.

Our machines are built for durability, with high-quality components that ensure a long lifespan. Depending on the frequency of use and maintenance, our machines typically last between 8 to 10 years, making them a valuable long-term investment.

Absolutely! We provide comprehensive after-sales support, including installation assistance, training, and technical support. Our team is always available to help you with any issues, ensuring your machines operate smoothly and efficiently throughout their lifespan.