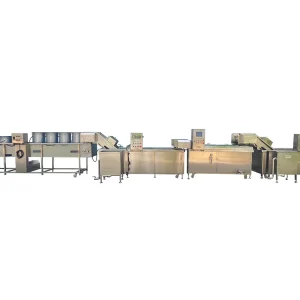

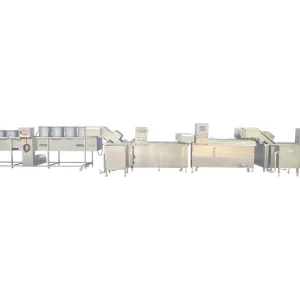

Features :

1. The whole machine is made of SUS304 stainless steel. The conveyor belt can be made of stainless steel chain net, stainless steel chain plate, etc. according to requirements. The machine runs smoothly, has low noise, low elasticity, is not easy to deform, and is easy to maintain.

2. The water temperature is automatically controlled by the temperature controller and can be set at will. The heat source can be steam heated, electric heated, etc., and the speed is variable frequency speed regulation. Double-layer insulation material is currently the most advanced food and vegetable leaching equipment in China.

3. The machine has low labor intensity, low manpower consumption, and high degree of automation. The temperature can be automatically adjusted within 95 degrees Celsius. The temperature difference between the upper and lower layers of water is small, and the product quality is easy to control. It is a rational equipment for the food processing industry.

4. The equipment solves the “randomness” caused by the low degree of automation in the sterilization process and strengthens the “consistency”, greatly improving the success rate of sterilization. It is an ideal production line equipment. The pasteurization line is divided into two parts: sterilization and cooling. Through the continuous operation of the chain, the sterilized objects are driven into the tank for continuous operation.

Process:

Each production line can be designed and customized according to the customer’s production process requirements, output, and site restrictions.

【Soaking and pre-washing elevator – Continuous peeling and cleaning machine – Connection elevator – 4-station selection conveyor belt – Slicer – Matching elevator – Automatic rinsing machine – Vibration drainer – Air drying line – Frying machine – Oil filter air cooling line – Seasoning machine】

Single Machine Use:

1. Soaking and pre-washing elevator: lift the potato raw materials into the peeling machine for peeling. The entrance can be made into a sinking stone tank to remove the mud and sand on the surface.

2. Continuous peeling and cleaning machine: wash and peel the potatoes →, with a cover on the top to prevent water from splashing out. Special sand sticks for potato peeling are made for efficient grinding. The stainless steel propeller drives the potatoes to the picking platform, and the speed of potato peeling can be controlled by the frequency converter.

3. Connecting elevator: The role of lifting and conveying solves the problem of manual feeding difficulties.

4. Manual picking line: manually select the washed and peeled potatoes to remove unclean places and unqualified materials.

5. Slicer: cut potatoes into slices of specified thickness, with adjustable cutting speed and customized slice thickness.

6. Matching elevator: The role of lifting and conveying solves the problem of manual feeding difficulties.

7. Automatic rinsing machine: rinse the cut potato slices/chips to remove the starch on the surface and prevent the chips and chips from sticking.

8. Vibration drainer: remove most of the water droplets on the surface of potato chips by high-frequency speed regulation and vibration drainage.

9. Air drying line: equipped with axial flow fan, so that the moisture of the material potato chips is blown away or evaporated in a short time, effectively preventing the oil from jumping during frying and shortening the frying time. A mesh cover is added on the top of the mesh belt to prevent the potato chips from being blown away. A water tray is added at the bottom.

10. Frying line: Purpose: fry and color the cooled potato chips and solidify them. The frying temperature is adjustable from 0 to 220°C, the frying time can be controlled, and the mesh belt is variable frequency speed regulation. With heat preservation.

11. Oil filter air cooling line: remove excess oil on the surface of potato chips after frying, and can also quickly cool down.

Seasoning machine: season and mix the material through the rotation of the drum. There is a leakage net at the discharge port, which can screen out the remaining seasoning and collect it for reuse, not only mixing the material evenly but also ensuring the integrity of the material.

Processing Effect :

The use of this equipment can greatly improve the effect and quality of potato processing and reduce many costs in the production process.

Certificate :

CE certified products, in line with ISO9001 quality standards, and have obtained a number of independent innovation technology patents.

Reviews

There are no reviews yet.