OEM Service

Wanlong offers a comprehensive OEM service, allowing customers to customize machines to their own processing materials and specifications. Our team of experts works closely to design and manufacture equipment to meet your unique requirements, ensuring high quality and functionality. Benefits include enhanced brand image, tailor-made solutions and increased market competitiveness.

Contact usCassava Processing Steps

Cassava processing involves several key steps to transform raw cassava roots into various food products or industrial materials. The typical process includes: Cleaning, Peeling, Washing, Cutting or Chipping, Drying.

Washing and Peeling

The peeled cassava is washed using bubble washing or spray washing machines to remove any remaining dirt.

Cutting or Chipping

Depending on the final product, cassava can be sliced, diced, or chipped for further processing.

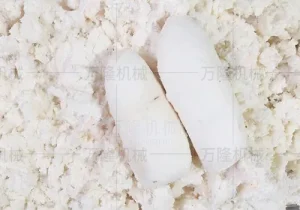

Grinding or Grating

The cassava pieces are ground or grated into a fine pulp to extract starch or produce cassava flour.

Design

Cassava processing machinery is designed to enhance efficiency, reduce labor intensity, and ensure product quality throughout the processing stages. The fundamental design principles and concepts include:

1. Automation and Efficiency

Modern cassava processing machines are designed for automation to minimize manual labor and improve productivity. Automated peeling, slicing, grinding, and drying systems increase efficiency and ensure consistent output.

2. Hygiene and Food Safety

Hygienic design is a key consideration, with stainless steel materials used for food-contact surfaces to prevent contamination. Machines are equipped with easy-to-clean structures, reducing bacterial growth and ensuring compliance with food safety standards.

3. Energy and Water Efficiency

Energy-saving technologies such as optimized heating systems in dryers and water recycling mechanisms in washing machines help reduce operational costs and environmental impact.

Cassava Processing Machinery Models

We provide high-quality cassava processing machinery designed to streamline the production process, ensuring efficiency, hygiene, and precision. Our equipment covers key processing stages, including cassava washing, peeling, and chopping.

Manufacturing

At our factory, we begin by thoroughly understanding our clients’ needs through detailed consultations, where we assess their specific requirements and production goals. Once we gather this information, our design team creates customized solutions tailored to those needs. After finalizing the design, we move to manufacturing, utilizing advanced technology and skilled labor to produce high-quality machinery. Throughout the production process, we maintain strict quality control standards. Finally, each completed machine undergoes rigorous testing to ensure optimal performance before shipping. This comprehensive approach ensures that we deliver reliable and efficient production line solutions that exceed our clients’ expectations.

Full Capacity in Our factory Manufacturing Plant

17+ Years

Industry Experience

Undertake large-scale kitchen project supporting assembly lines.

3000+㎡

Production Base

The factory produces more than 50 machines per month.

300+ Clients

Cooperative Enterprises

Cooperate with many well-known food brand companies.

How to produce machinery step by step?

#1 Design and Engineering:

Our skilled engineers create detailed designs using advanced software, ensuring each machine meets specific client requirements and industry standards for functionality and efficiency.

#2 Machining and Fabrication:

High-precision machining processes are employed to fabricate components from quality materials, guaranteeing durability and performance. This stage utilizes cutting-edge technology for accuracy in production.

#3 Assembly and Quality Testing:

Components are meticulously assembled by trained technicians, followed by rigorous quality testing to ensure each machine operates optimally and meets all safety and performance criteria.

After-Sales Service

Service throughout the entire lifespan of your product

- Contact Customer Service One-to-one service!

- Free design of a full set of production line solutions.

- Provide nationwide installation and delivery services.

- Pre-sales, in-sales and after-sales/ensure worry-free after-sales.

- Quote within 2 hours/A large number of video cases for reference.

Need support?

We’re 24/7/365 at your service!

At Foshan Wanlong Food Processing Machinery, we provide comprehensive pre-sales, in-sales, and after-sales services. From initial consultations and product customization to installation, training, and ongoing support, we ensure our customers receive exceptional service at every stage of their experience.

Want Support Now