Fruit and Vegetable Cleaning Machine

This vegetable washing machine uses bubble cleaning to effectively separate the attached materials on the surface of the washed objects, simulates the basic movements of manual cleaning and effectively avoids the bumps, knocks, scratches and other phenomena in manual cleaning, thus improving work efficiency.

The machine is equipped with a circulating filtration system and an activated carbon filtration device. The water in the pool continuously passes through the water pump and is filtered through activated carbon to achieve the purpose of purifying the water. The floating objects are discharged from the overflow port; the dirt sunk to the bottom of the pool is discharged from the bottom.

Types of Vegetable Washing Machine

Single Cylinder Cleaning Machine

Model: QB-1

Material: All stainless steel

Power supply: 380V/220V

Power: 1.5kw

Dimensions: 1000×700×1000mm

Processing capacity: 200-300 kg/hour

Double-cylinder cleaning machine

Model: QB-2

Material: All stainless steel

Power supply: 380V/220V

Power: 1.5kw

Processing capacity: 300-400kg/H

Dimensions: 1500×800×1000mm

Vegetable Bubble Cleaning Machine

Model: QB-25

Material: All stainless steel

Power: 3.3KW

Output: 500KG/H

Net weight: 260KG

Dimensions: 2700×1150×1550mm

High Pressure Spray Cleaning Machine

Model: QB-35

Material: All stainless steel

Water pump power: 1.1kw

Air pump power: 5.5kw

Elevator power: 0.2kw

Output: 800KG/H

Dimensions: 3700×980×1500mm

External Circulation Filter Cleaning Machine

Model: QB-35K

Material: 304 stainless steel

Power supply: 380V/50HZ

Power: 1.1kw

Dimensions: 3700×1460×1550mm

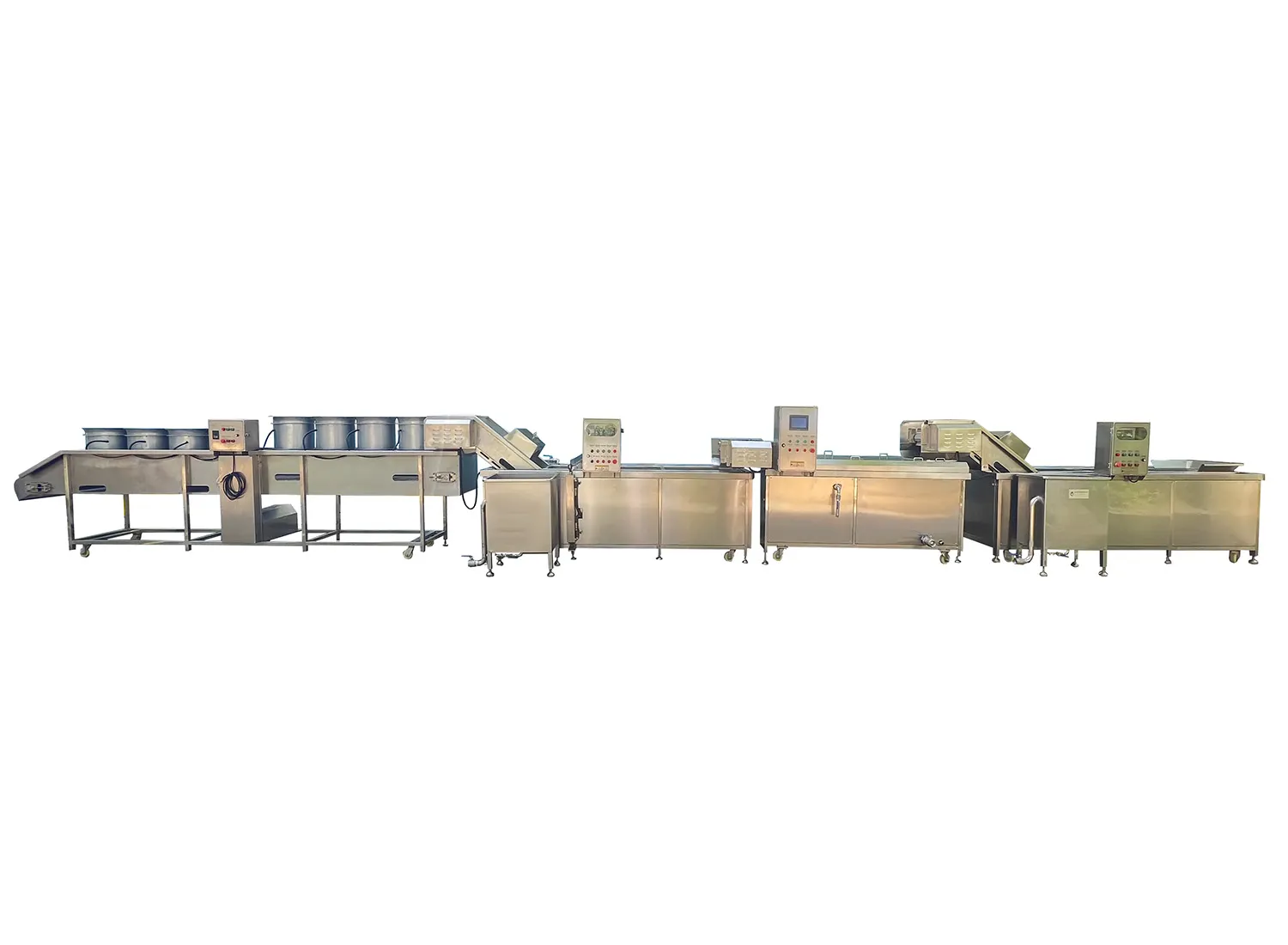

Pest and Debris Removal Cleaning Machine

Model: QB-60

Material: 304 stainless steel

Power supply: 380V/50HZ

Power: 5kw

Dimensions: 6000×950×1300mm

Processing capacity: 2000 kg/hour

Continuous Fruit Washing Machine

Model: QX-30

Voltage: 220V/380V

Power: 2.2kw

Net weight: 220kg

Dimensions: 3500*970*1140mm

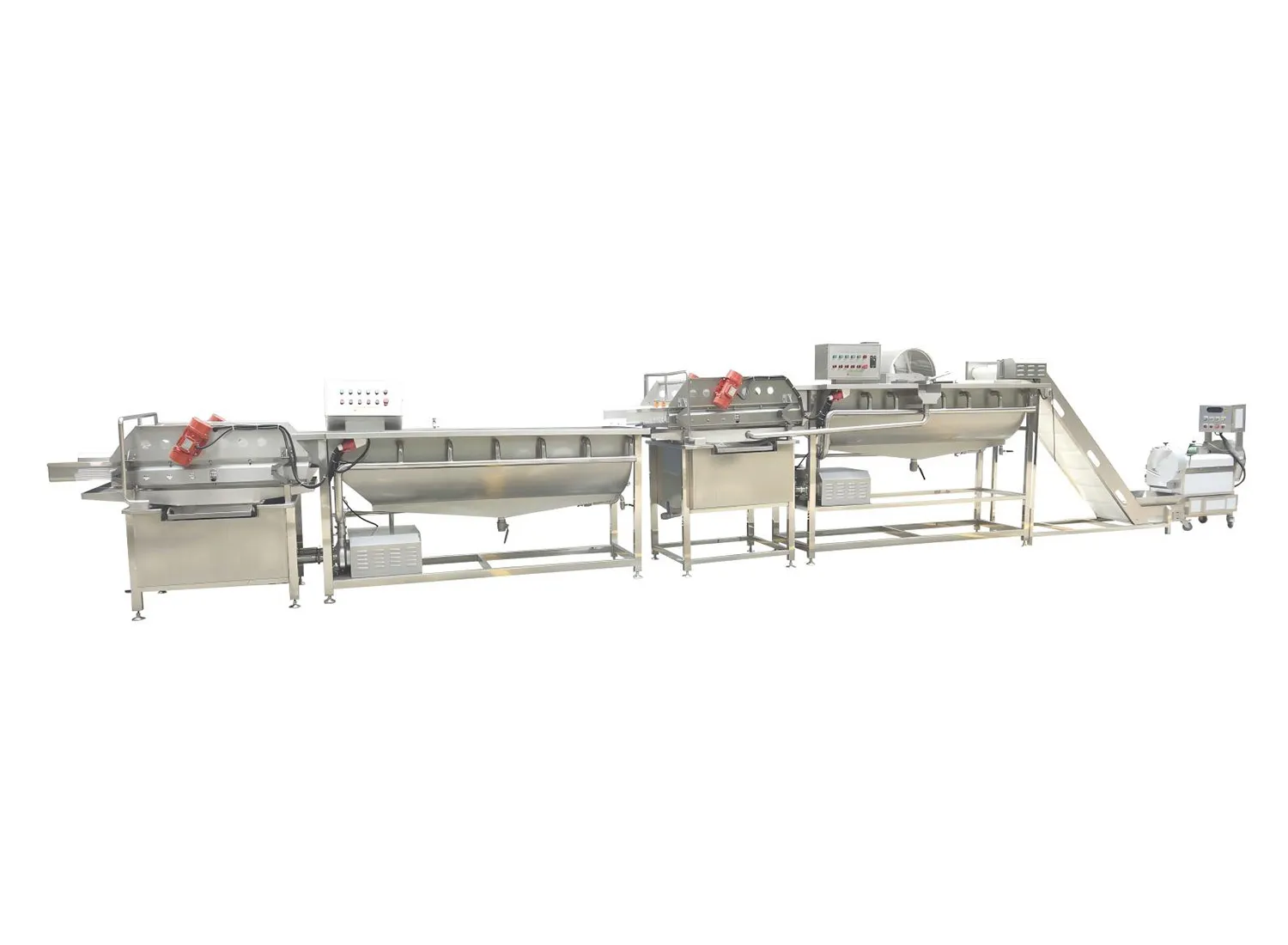

Eddy Current Cleaning Machine

Voltage: 380V

Power: 7.5kW

Material: SUS304 stainless steel

Production: about 1000kg/hour

Size: 8500*1300*2000mm

Application

It can effectively degrade bacteria and pesticide residues on the surface of fruits and vegetables, thaw fresh meat to remove blood, remove seafood microorganisms, etc., and retain the original flavor of the ingredients.

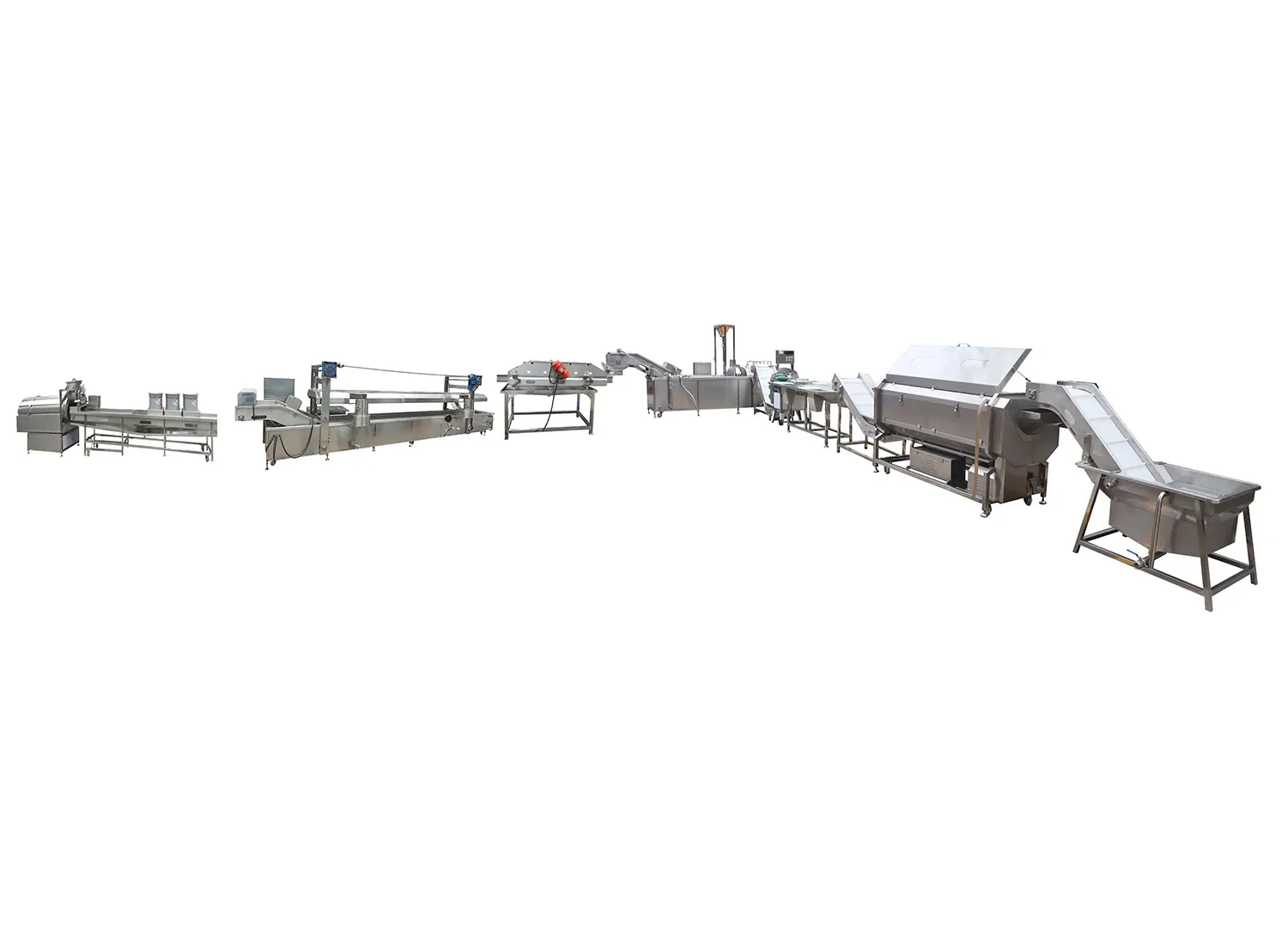

OEM Customized Processing Production Line

Potato Chips Production Line

Feed soaking → cleaning and peeling → elevator → picking line → lifting feed → slicer → rinsing starch → vibration draining → frying line → wind degreasing → seasoning

Cleaning and Air Drying Frying Line

Lifting feed → cleaning and peeling → picking line → lifting feed → slicer → rinsing starch → vibration draining → wind blowing draining → lifting feed → frying line

Salad Vegetable Production Line

Feed cutting → lifting and conveying → cleaning line → secondary cleaning → vibration drainage → water removal and air drying → packaging

Meat Washing and Blanching Line

Lifting feed → cleaning → blanching line → cleaning machine → air drying line

Cleaning Machine Effect

(1) Bubble rinsing: more thoroughly cleans vegetables and separates impurities.

(2) Water circulation surfing: spray rinsing, deep cleaning of vegetables, quick decontamination.

(3) Ozone sterilization: degrades pesticide residues and fruit wax, leaving bacteria and stains nowhere to escape.

(4) No damage to fruits and vegetables: surfing and rolling imitates manual cleaning without damaging the leaves.

(5) Selected materials: the whole machine is made of stainless steel, which is sturdy and durable, anti-corrosion and anti-rust.

(6) Technology upgrade: energy saving and water saving, lower energy consumption, efficient and clean.

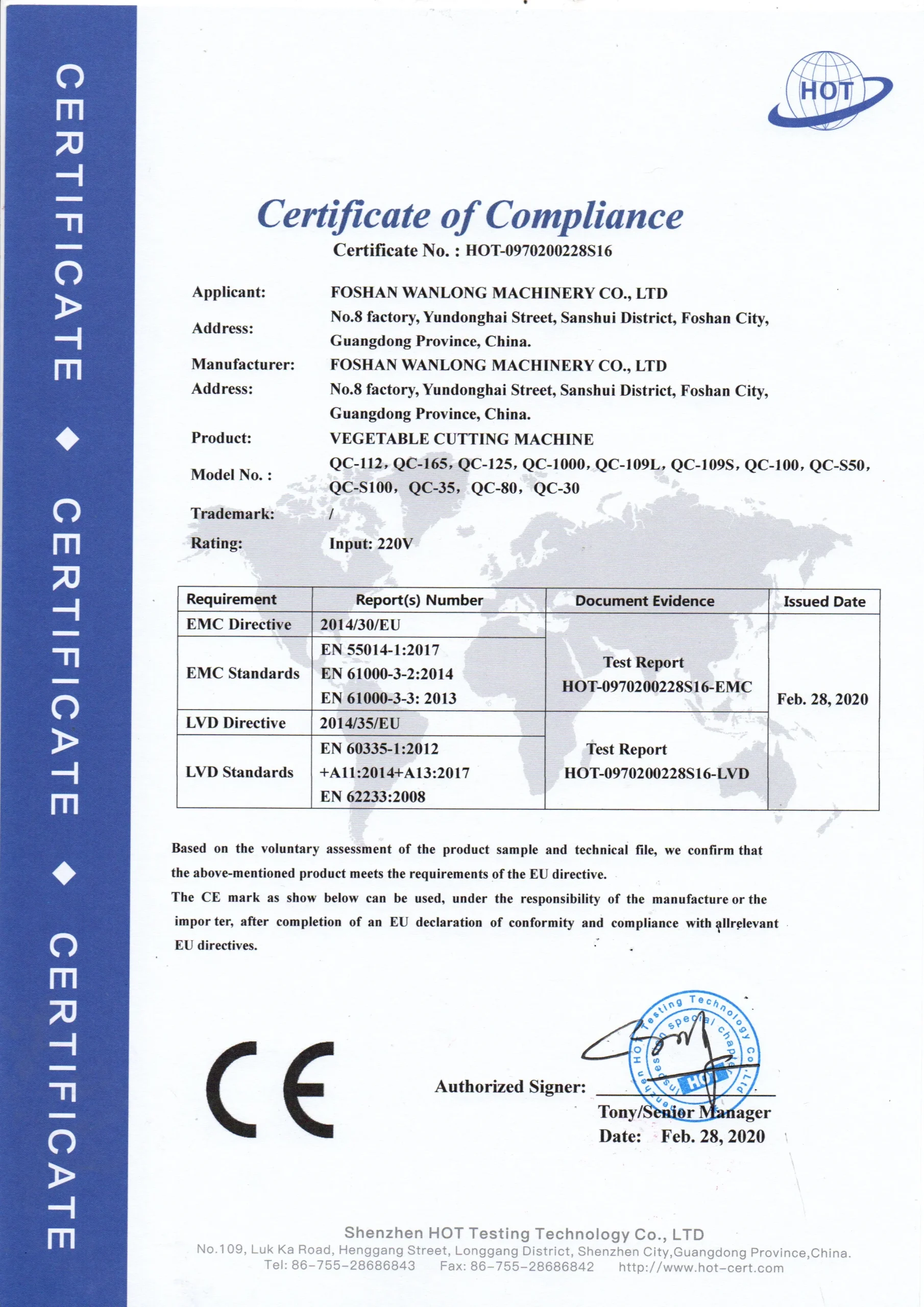

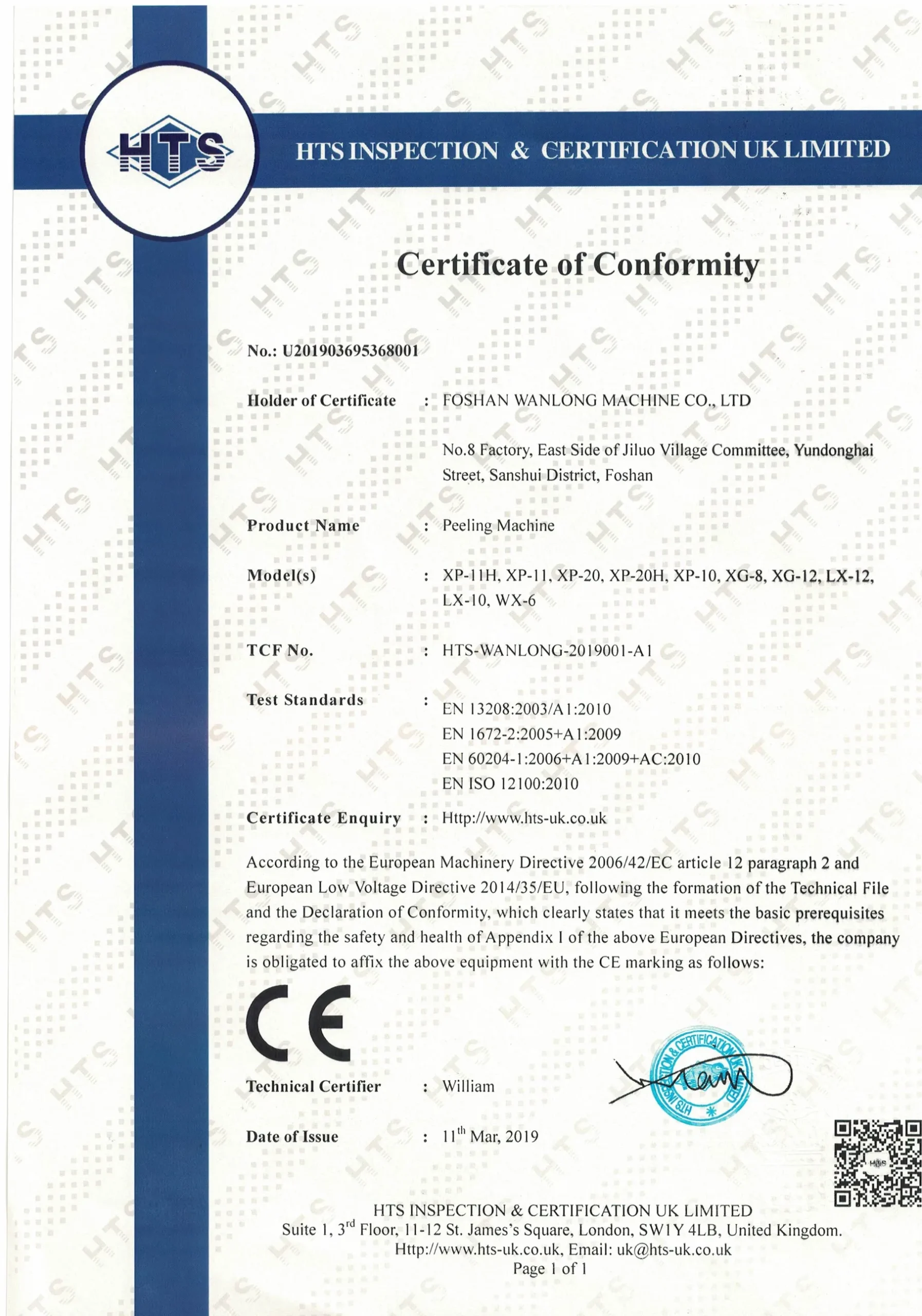

Our Certificates

FAQs

Our washing machines are versatile and can handle a wide range of vegetables, including leafy greens and root vegetables, as well as various meat products.

The machine utilizes high-pressure water jets and bubble technology to remove dirt, pesticides, and other contaminants effectively, ensuring thorough and hygienic cleaning.

Yes, the washing machine is designed to be gentle on delicate vegetables, preventing damage while ensuring they are cleaned thoroughly.

Absolutely. Our machines offer adjustable water pressure and cleaning cycles to accommodate different types of produce and degrees of dirtiness.

Regular maintenance includes cleaning the water filters, checking and replacing worn parts, and ensuring the nozzles and conveyors are free of debris for optimal performance.

Yes, our washing machines are designed to be energy-efficient, using advanced technology to minimize water and power consumption while maintaining high cleaning standards.