OEM 服务

万隆提供全面的 OEM 服务,允许客户根据自己的加工材料和规格定制机器。我们的专家团队密切合作,设计和制造符合您独特要求的设备,确保高质量和功能性。这样做的好处包括提升品牌形象、量身定制解决方案和提高市场竞争力。

联系我们Cassava Processing Steps

Cassava processing involves several key steps to transform raw cassava roots into various food products or industrial materials. The typical process includes: Cleaning, Peeling, Washing, Cutting or Chipping, Drying.

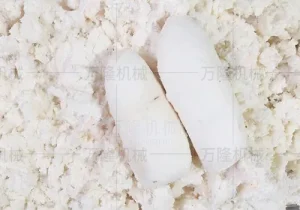

Washing and Peeling

The peeled cassava is washed using bubble washing or spray washing machines to remove any remaining dirt.

Cutting or Chipping

Depending on the final product, cassava can be sliced, diced, or chipped for further processing.

Grinding or Grating

The cassava pieces are ground or grated into a fine pulp to extract starch or produce cassava flour.

设计

Cassava processing machinery is designed to enhance efficiency, reduce labor intensity, and ensure product quality throughout the processing stages. The fundamental design principles and concepts include:

1. Automation and Efficiency

Modern cassava processing machines are designed for automation to minimize manual labor and improve productivity. Automated peeling, slicing, grinding, and drying systems increase efficiency and ensure consistent output.

2. Hygiene and Food Safety

Hygienic design is a key consideration, with stainless steel materials used for food-contact surfaces to prevent contamination. Machines are equipped with easy-to-clean structures, reducing bacterial growth and ensuring compliance with food safety standards.

3. Energy and Water Efficiency

Energy-saving technologies such as optimized heating systems in dryers and water recycling mechanisms in washing machines help reduce operational costs and environmental impact.

Cassava Processing Machinery Models

We provide high-quality cassava processing machinery designed to streamline the production process, ensuring efficiency, hygiene, and precision. Our equipment covers key processing stages, including cassava washing, peeling, and chopping.

制造业

在我们的工厂,我们首先通过详细的咨询来全面了解客户的需求,评估他们的具体要求和生产目标。收集到这些信息后,我们的设计团队会根据这些需求量身定制解决方案。在确定设计方案后,我们便开始制造,利用先进的技术和熟练的劳动力生产出高质量的机器。在整个生产过程中,我们坚持严格的质量控制标准。最后,每台完成的机器都要经过严格的测试,以确保在发货前达到最佳性能。这种全面的方法确保我们提供可靠、高效的生产线解决方案,超越客户的期望。

我们的工厂满负荷生产

17+ 年

行业经验

承担支持装配线的大型厨房项目。

3000+㎡

生产基地

工厂每月生产 50 多台机器。

300+ 客户

合作企业

与众多知名食品品牌公司合作。

如何逐步生产机械?

#1 设计与工程:

我们技术娴熟的工程师使用先进的软件进行详细设计,确保每台机器都能满足客户的具体要求,并符合功能和效率方面的行业标准。

#2 加工和制造:

采用高精度加工工艺,用优质材料制造部件,确保耐用性和性能。这一阶段采用最先进的技术,以确保生产的精确性。

#3 装配和质量检测:

部件由训练有素的技术人员精心组装,然后进行严格的质量检测,以确保每台机器都能以最佳状态运行,并符合所有安全和性能标准。