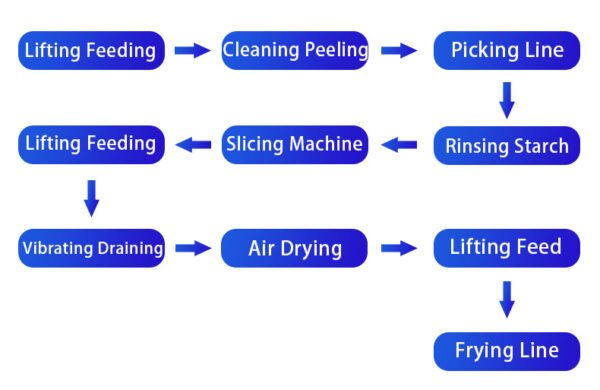

Automatic Potato Processing Line

Product:

The use of this potato processing machine can greatly improve the effect and quality of vegetable processing, reduce multiple costs in the production process, and make your products more competitive in the market.

Services:

Can be customized on demand

Customized whole factory assembly line

Intelligent automated operation

Product details

1. The whole machine is made of SUS304 stainless steel. The conveyor belt can be made of stainless steel chain net, stainless steel chain plate, etc. according to requirements. The machine runs smoothly, has low noise, low elasticity, is not easy to deform, and is easy to maintain.

2. The water temperature is automatically controlled by the temperature controller and can be set at will. The heat source can be steam heated, electric heated, etc., and the speed is variable frequency speed regulation. Double-layer insulation material is currently the most advanced food and vegetable leaching equipment in China.

3. The machine has low labor intensity, low manpower consumption, and high degree of automation. The temperature can be automatically adjusted within 95 degrees Celsius. The temperature difference between the upper and lower layers of water is small, and the product quality is easy to control. It is a rational equipment for the food processing industry.

4. The equipment solves the "randomness" caused by the low degree of automation in the sterilization process and strengthens the "consistency", greatly improving the success rate of sterilization. It is an ideal production line equipment. The pasteurization line is divided into two parts: sterilization and cooling. Through the continuous operation of the chain, the sterilized objects are driven into the tank for continuous operation.

Parameter

| Machine Name: | Lifting Machine |

| Power supply: | 380V Three-phase, 0.25KW Adjustable Speed |

| Machine dimensions: | 2650*800*1900mm |

| Material: | White food-grade PP chain conveyor; |

| Functions: | It serves to lift and convey materials, solving the problem of difficulty in manual feeding. |

| Machine Name: | Automatic washing and peeling machine |

| Power Supply: | 380V, three-phase |

| Power: | 3kw |

| Features: | 1. The entire machine is made of 304 stainless steel to national standards. |

| 2. All brush rollers are made of solid shafts. | |

| 3. The cylinder has a U-shaped arc design and uses 8 1010 nylon brushes, utilizing a differential speed design for tumbling and friction cleaning. | |

| 4. The motor is from the well-known domestic brand, Dedong Motor. |

| Machine Name: | Selection Conveyor Line |

| Dimensions: | 4000*600*400mm |

| Total Power: | 1.1KW |

| Material: | Outer Frame: 304 Stainless Steel |

| Functions: | Motor: Variable Frequency Speed Adjustment |

| Application: | Peeled potatoes are transported to this selection platform, where damaged or rotten potatoes are manually sorted out. |

| Machine Name: | Double-headed vegetable cutting machine |

| Model: | QC-112 |

| Voltage: | 220V |

| Power: | 1.1KW |

| Weight: | 165KG |

| Dimensions: | 1070*1100*530MM |

| Application: | The dual-head vegetable cutter has dual frequency modulation function. One head is for cutting leafy vegetables, such as scallions, garlic sprouts, chives, celery, cabbage, and bok choy, while the other head is for cutting root vegetables, such as radishes, potatoes, sweet potatoes, taro, bamboo shoots, onions, eggplants, apples, ginger, and many other fruits and vegetables. |

| Machine Name: | Connecting Lifting Machine |

| Dimensions: | 2500*800*1300mm |

| Power: | 250w |

| Purpose: | Lifting and conveying, solving the problem of difficult manual feeding. |

| Machine Name: | Cleaning equipment |

| Voltage: | 380V Three-phase |

| Power: | 3.7KW |

| Speed: | Adjustable speed |

| Machine Dimensions: | 3750*1400*14500mm |

| Application: | 1. The material undergoes bubble washing, ensuring a thorough surface clean. A secondary spray cleaning function is provided. The bottom is equipped with a full stainless steel chain belt drive, eliminating cleaning gaps. 2. All internal edges and corners are trimmed to prevent residue or incomplete material conveying. A flow guide at the discharge port prevents material from being carried back. 3. The conveyor belt is made of full stainless steel chain plates, meeting food-grade standards and facilitating easy cleaning. |

| Machine Name: | Vibrating Drainer |

| Voltage: | 80V |

| Power: | 1.5KW |

| Size: | 1850*750*1100MM |

| Configuration: | Variable Frequency Speed Control |

| Functions: | This linear vibrating dewatering screen utilizes the principle of two opposing vibrating motors to excite the material, causing it to move in a jumping linear motion on the screen surface. |

| Machine Name: | Air drying machine |

| Belt Width: | 600mm |

| Total Power: | 8KW |

| Dimensions: | 5500*1100*1300mm |

| Configuration: | Equipped with a high-pressure blower, adjustable speed, two-layer tilting structure |

| Application: | 1. The entire machine uses a three-layer stainless steel mesh chain drive for conveying and discharging materials. 2. Automatic tilting with adjustable speed. 3. The drying air is at room temperature, effectively protecting the color and quality of the materials. 4. Surface drying of vegetables, fruits, meats, and other materials. |

| Machine Name: | Deep frying machine |

| Voltage: | 380V |

| Power: | 8KW |

| Dimensions: | 5500*1200 (including oil filter)*1500mm |

| Chain plate width: | 800mm |

| Configuration: | Speed and temperature adjustable |

| Functions: | The entire machine is constructed of food-grade 304 stainless steel, incorporating multiple material conveying structures to prevent uneven frying or burning of materials due to material accumulation. |

Contact us

Foshan Wanlong Machinery Co., Ltd.

- WhatsApp: +8618928568496

- WeChat: +8618928568496

- Phone: +8618928568496

- Email: yan@fswljx.com

- Address: Workshop 1-2, No. 24-7, Zone C, Southwest Park, Sanshui Industrial Zone, Foshan

Get A Quote

- Please share your custom requirements (capacity, output, space, etc.) for an accurate quote.

- Let us know your Email/WhatsApp/WeChat so we can respond quickly.

- We’ll contact you within 24 hours with a tailored solution!