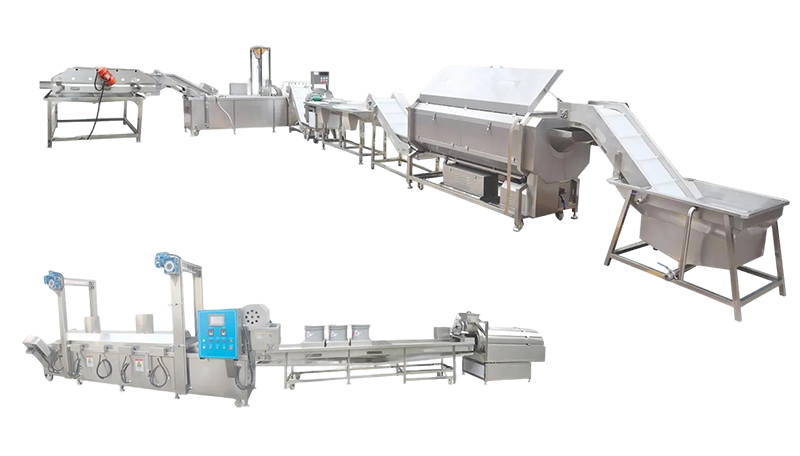

Complete Cassava Processing Solution:

From Washing to Frying

Since installing the Wanlong cassava processing production line, the customer's production capacity has increased by 30%!

CONTACT US NOW FOR A FREE PRODUCT CUSTOMIZATION PROPOSAL!

Features of Automated Cassava Processing Production Line

- Automatic Washing: Equipped with water jets and brushes to effectively clean root vegetables.

- Peeling Mechanism: Integrated peeling system that gently removes skins without damaging the core.

- Dicing Functionality: Precision dicing tools provide uniform cuts, ensuring smooth and intact surfaces.

- Material Handling: Designed with conveyors and feeders for seamless transitions between stages.

- Control System: A user-friendly interface for easy operation and control of the process.

Advantages of Cassava Washing & Peeling Production Line

Professional Customized Services

Full customization of capacity, voltage & dimensions | Factory layout planning included | Built with 304 stainless steel & premium components (e.g., Siemens) for consistent quality

Applciation of Commercial Cassava Processing Line

The Cassava Cleaning, Peeling, and Cutting Production Line is specially designed for the preprocessing of cassava and the handling of root vegetables such as carrot, sweet potatoes, potatoes, ginger, and others. This comprehensive production line is engineered to provide an efficient process for washing, peeling, dicing, and draining root vegetables, ensuring minimal damage to the materials. It is an ideal solution for agricultural product processing, with a high degree of automation and user-friendly operation.

Main Processing Steps of Potato Chips Production Line

1. Soaking Conveyor

Used for lifting and conveying materials, it can soak the materials and soften the soil on the surface of the materials.

Sus304 stainless steel body + food grade PP conveyor belt

2. Continuous Peeling Machine

The potatoes pass through the elevator and enter the spiral peeling machine to completely remove the potato skin. The special sanding stick for potato peeling is highly efficient.

3. Connection Elevator

The functions of lifting and conveying can solve the problem of difficult manual feeding.

4.4-station Selection Conveyor Belt

The peeled potatoes are transported to this sorting platform, where damaged or rotten potatoes are manually sorted. High-quality PP white conveyor belts are used.

5. Slicer

The conveyor belt speed and the rotating knife speed are adjustable by frequency converter and can be controlled independently. Different cutting thickness can be achieved by configuring the knife disc with different cutting sizes.

6. Matching Elevator

The functions of lifting and conveying can solve the problem of difficult manual feeding.

7. Automatic Bubble Cleaning Machine

1. After the potato chips are washed with bubbles, the surface starch is fully washed, and the machine performs secondary spray cleaning. The bottom is driven by a stainless steel chain plate, with no cleaning gap.

2. All corners inside the machine are trimmed to prevent residue or incomplete conveying. There is a diversion device at the conveying outlet to prevent the material from being brought back.

3. The machine has a variable frequency speed regulation function.

4. The conveyor belt is a full stainless steel chain conveyor, which meets food grade standards and is easy to clean.

Configuration:

1. Inverter: TECO; Transmission motor: Wanxin 2. Contactor, relay, circuit breaker: Schneider 3. Circulation spray configuration above the machine

8. Vibration Drainer

This linear vibration draining machine uses the principle of two vibration motors with opposite directions to make the material move linearly on the screen surface in a jumping manner.

Features: The machine uses Italian vibration module.

9. Frying Machine

1. The chain plate transmission adopts variable frequency stepless speed regulation, and the frying time is controllable.

2. The equipment is equipped with an automatic lifting system, and the upper cover and mesh belt can be raised and lowered for easy cleaning.

3. The bottom is equipped with a slag discharge system to discharge the residue at any time.

4. The high-efficiency thermal conductivity device is adopted, and the energy utilization rate is high, which is conducive to reducing enterprise costs.

5. The whole machine is made of food-grade 304 stainless steel, and a variety of material guide and conveying structures are combined to prevent the frying materials from piling up and frying unevenly or becoming mushy.

6. The upper and lower double-layer mesh belts are used for transmission, and the product is sandwiched between the double-layer mesh belts to prevent the product from floating.

10. Oil Filter Air Drying Line

The air drying line is made of high-quality 304 stainless steel with adjustable conveying speed. Three high-pressure circular blowers are used to air dry the potatoes, which are transported by mesh belts to accelerate the cooling of the French fries and dry the surface moisture for subsequent processing.

11. Seasoning Machine

The seasoning machine consists of a base support, a rotating drum, a powder feeding device, a transmission system and a speed control system. It can automatically control the speed and capacity of the material and is suitable for continuous seasoning operations in the assembly line. The material falls into the drum pushed upward by the mixing blades and falls from above to mix with the seasoning powder.

FAQs

Our cassava processing line includes washing, peeling, cutting, blanching, and frying machines, providing a complete solution for cassava processing.

Yes, we offer fully customizable lines based on your capacity, product type, and specific needs.

Our machines are energy-efficient, reducing power consumption and operational costs. We provide detailed estimates based on your configuration.

Installation typically takes 2-4 weeks, including testing and optimization before production starts.

We offer installation, training, maintenance, and a warranty on all machines, along with spare parts availability.

Yes, we ship globally and provide installation services at your location, along with operator training.