Blog

What types of commercial vegetable cutting machine are there?

Vegetable cutters play a crucial role in streamlining food preparation, ensuring consistency, and saving valuable time. With a variety of commercial vegetable cutters available, each designed for specific tasks, understanding the different types can help you choose the best equipment for your needs. In this article, we’ll explore the various types of commercial vegetable cutters, their features, and their applications.

Manual Vegetable Cutters

Manual vegetable cutters are basic yet versatile tools used in many commercial kitchens. They rely on human effort to operate, typically involving a hand-cranked mechanism or a push-down blade system.

1.1. Slicer and Dicer Models: Manual slicers and dicers are popular for their simplicity and affordability. They allow users to cut vegetables into uniform slices or dice them into small cubes. These models are often equipped with adjustable blades to achieve different thicknesses and sizes.

1.2. Julienne Cutters: Manual julienne cutters are designed to produce long, thin strips of vegetables, ideal for salads and garnishes. These tools often feature multiple blades or a grid pattern to create consistent julienne cuts.

1.3. Benefits and Limitations: Manual cutters are cost-effective and easy to maintain, making them suitable for small to medium-sized operations. However, they require physical effort and may not be ideal for high-volume kitchens due to the time and labor involved.

Electric Vegetable Cutters

Electric vegetable cutters, also known as commercial food processors, offer enhanced efficiency and versatility compared to manual models. These machines use electric motors to power the cutting blades, reducing manual labor and increasing throughput.

2.1. Commercial Food Processors: These versatile machines come with various attachments and blades, allowing for multiple cutting styles such as slicing, dicing, grating, and shredding. They are suitable for handling large volumes of vegetables and can save significant time in busy kitchens.

2.2. Batch Cutters: Electric batch cutters are designed to process larger quantities of vegetables in one go. They typically feature large bowls and powerful motors, making them ideal for restaurants and foodservice operations with high-volume needs.

2.3. Benefits and Limitations: Electric cutters offer high efficiency and consistent results, making them a great choice for large-scale food preparation. However, they come with a higher initial cost and require more maintenance compared to manual cutters.

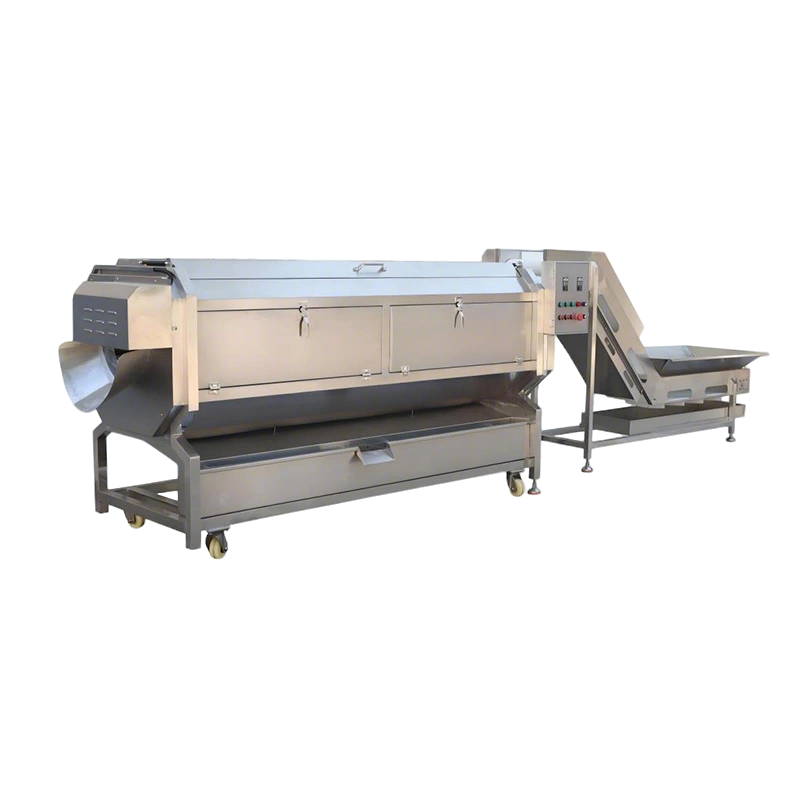

Industrial Vegetable Cutters

Industrial vegetable cutters are heavy-duty machines designed for large-scale food production. They are built to withstand the rigors of continuous use and are equipped with advanced features to handle diverse cutting tasks.

3.1. High-Volume Slicers and Dicers: These machines are engineered for high-capacity operations, capable of slicing and dicing large quantities of vegetables quickly and uniformly. They often come with multiple blade options and adjustable settings to accommodate different produce types.

3.2. Multi-Functional Cutters: Industrial multi-functional cutters are equipped with various attachments for slicing, dicing, chopping, and shredding. These machines offer versatility and can handle a wide range of vegetables, making them suitable for diverse food processing needs.

3.3. Benefits and Limitations: Industrial cutters are ideal for large food processing facilities and commercial kitchens with high-volume requirements. They provide superior efficiency and durability but come with a higher price tag and require dedicated space.

Specialized Vegetable Cutters

Specialized vegetable cutters are designed to handle specific cutting tasks or types of vegetables. These machines offer targeted functionality to meet particular culinary needs.

4.1. Mandolins: Commercial mandolins are used for precise slicing and can produce various thicknesses and shapes, including julienne and waffle cuts. They are compact and easy to use, making them a popular choice for chefs who need precise control over their cuts.

4.2. Corn Cutters: Designed specifically for removing kernels from corn cobs, these cutters streamline the process and reduce waste. They are especially useful in kitchens that frequently prepare corn-based dishes.

4.3. Onion and Garlic Choppers: Specialized choppers for onions and garlic make it easier to achieve fine, consistent cuts while minimizing strong odors and reducing manual effort. These cutters are designed to handle the unique texture of these vegetables.

4.4. Benefits and Limitations: Specialized cutters offer targeted solutions for specific tasks, enhancing efficiency and precision. However, they may not be as versatile as multi-functional models and may require additional storage space.

Countertop vs. Floor Models

Commercial vegetable cutters come in both countertop and floor models, each suited to different kitchen setups and needs.

5.1. Countertop Models: These are compact and designed to fit on countertops, making them ideal for smaller kitchens or establishments with limited space. They are suitable for moderate to high-volume use and can be easily accessed by kitchen staff.

5.2. Floor Models: Floor-standing models are larger and designed for high-volume operations. They offer greater capacity and are often used in large kitchens or food processing facilities. These models are equipped with more powerful motors and larger bowls.

5.3. Benefits and Limitations: Countertop models are space-efficient and suitable for smaller operations, while floor models provide greater capacity and durability for high-volume needs. The choice between the two depends on the size and requirements of the kitchen.

Conclusion

Choosing the right commercial vegetable cutter can significantly impact the efficiency and quality of food preparation in a restaurant or food processing facility. Whether you opt for manual, electric, industrial, or specialized models, each type offers unique benefits and is suited to different needs. By understanding the various options available, you can select the best cutter to enhance your kitchen’s operations, improve consistency, and ultimately deliver exceptional dishes to your customers.

As you evaluate your options, consider factors such as volume requirements, versatility, and budget. Investing in the right vegetable cutter will streamline your food preparation process, save time, and ensure that your produce is cut to perfection every time.